Views: 0 Author: Site Editor Publish Time: 2025-09-19 Origin: Site

Designing injection molded parts is both an art and a science. It’s not just about shaping plastic but creating parts that are strong, functional, and visually appealing. They must fill the mold correctly, cool evenly, and eject smoothly—all while keeping costs under control. Whether you’re designing everyday consumer products or precision engineering components, understanding the principles of injection molding is key. In this guide, we explore everything you need to know—from choosing the right material and wall thickness to designing ribs, draft angles, and cosmetic features—so you can make high-quality, manufacturable parts every time.

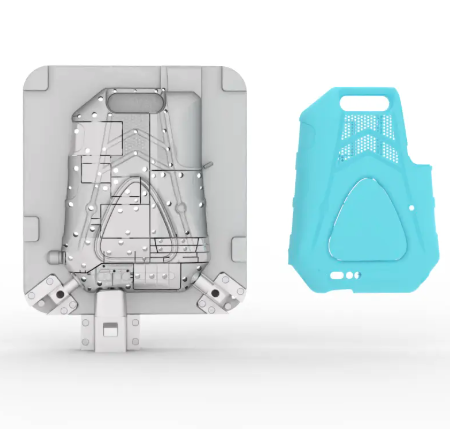

Injection molding is a widely used method for making plastic parts fast and precisely. It works by injecting molten material into a mold, letting it cool, and then removing the solid part. They can produce complex shapes in large quantities without losing accuracy.

Injection: Molten plastic is pushed into a mold cavity under high pressure.

Cooling: Water channels cool the part quickly, reducing cycle time.

Ejection: The finished part is pushed out of the mold using ejector pins.

| Step | Purpose | Key Considerations |

|---|---|---|

| Injection | Fill the mold completely | Flow rate, pressure, temperature |

| Cooling | Solidify the part efficiently | Channel layout, cycle time |

| Ejection | Remove the part without damage | Draft angles, friction |

Injection molding machines have hoppers for material, heated barrels for melting, and clamps to hold the mold tightly. Every part’s shape affects how it flows, cools, and comes out.

Choosing the right material impacts every stage, from design to production. Plastics can be thermoplastic (reusable) or thermoset (harden permanently). They vary in strength, flexibility, heat resistance, and shrinkage.

Strength and durability affect wall thickness, ribs, and bosses.

Chemical resistance influences which plastics work for the product.

Flow properties determine if thin sections or intricate shapes will fill properly.

| Material Type | Typical Uses | Notes |

|---|---|---|

| Polypropylene (PP) | Living hinges, containers | Flexible, chemical resistant |

| ABS | Electronics housings | Stiff, moderate heat resistance |

| Nylon (PA) | Gears, mechanical parts | Strong, absorbs moisture |

| PEEK | High-performance parts | Expensive, very heat resistant |

They also affect cycle time, ejection methods, and tool wear. Using the wrong material can cause warping, poor surface finish, or even mold damage.

Uniform wall thickness is crucial. It allows the plastic to flow evenly, cool evenly, and reduces defects like warping or sink marks. Uneven walls often lead to weak spots or costly rework.

Keep walls as consistent as possible.

Minimum wall thickness depends on material and geometry.

Ribs should be 50–75% of main wall thickness.

Avoid abrupt changes, sharp corners, or sudden thick spots.

| Material | Min Wall Thickness | Typical Max Rib Thickness |

|---|---|---|

| PP | 0.8 mm | 0.6 mm |

| ABS | 1.0 mm | 0.7 mm |

| Nylon | 1.0–1.5 mm | 1.0 mm |

They ensure proper mold fill, reduce sink marks, and maintain part strength. Draft angles also help ejection, especially in thicker parts.

Draft angles let parts release easily from molds. Vertical walls need a slight taper so they slide out without friction. Sharp corners cause stress points and may trap air or cause sink marks.

Smooth surfaces: 1–2° draft

Textured surfaces: 3–5° draft

Apply to ribs, bosses, and corners

Align draft with mold parting lines

Corners should be rounded, ideally 0.5–2× wall thickness. Fillets reduce stress, guide material flow, and improve overall appearance.

Ribs add strength without thickening the wall. They guide material flow and prevent warping. Proper placement is key to avoid sink marks.

Thickness: 50–75% of attached wall

Height: Max 3× wall thickness

Spacing: At least 2× rib thickness

Use fillets at junctions to reduce stress

Gussets reinforce corners or load-bearing areas. Cross-ribs can be tricky but improve structural integrity when used carefully.

Undercuts require extra mold actions like sliders or lifters. Use them only where essential. Snap-fits and clips let parts attach without screws. Living hinges allow repeated flexing, commonly in polypropylene parts.

Living hinges: thin zone (0.25–0.5 mm), straight axis, rib reinforcement

Snap-fits: enough flex without breaking, clear tolerances

Undercuts: plan parting line, avoid interference between sliders

These features save assembly time but increase tooling complexity. Proper planning avoids defects and simplifies production.

Parts often carry branding. Raised or recessed text should be clear, legible, and sized for molding. High-aspect details or sharp lines are difficult to reproduce.

Use simple fonts (sans-serif)

Keep height and thickness adequate

Apply draft angles to prevent sticking

Avoid placement on vertical or highly drafted surfaces

Surface texture affects both appearance and mold release. Textured areas may require larger draft angles to maintain quality.

Designing for manufacturing involves careful consideration to avoid costly errors. Uneven wall thickness can lead to warping, a defect that distorts the shape of the part and can render it unusable. Inadequate draft angles can slow down the ejection process, increasing cycle time and potentially damaging the part. Sharp corners are notorious for creating stress points, which can lead to part failure under load. Complex undercuts not only increase the complexity of the mold but also raise production costs due to the need for additional slides or lifters. Poor gate placement can affect the flow of material, leading to incomplete fills, voids, or other defects. Lastly, choosing the wrong material can reduce part performance, either by making it too brittle or too flexible for its intended use. Identifying these mistakes early in the design phase can save significant time, cost, and reduce production delays.

Embarking on the journey of injection molding design requires a methodical approach to ensure the final product is not only functional but also efficient in its manufacturing process. Here’s a detailed step-by-step guide to crafting a successful design:

Identify Function, Load, and Environment

Begin by thoroughly understanding the part’s intended function, the loads it will bear, and the environment in which it will operate. This initial assessment is crucial for determining the necessary material properties and design features that will ensure the part’s reliability and longevity.

Choose Material Based on Strength, Flow, and Heat

Select the appropriate material considering its strength, flow characteristics, and heat resistance. The material must be capable of withstanding the operational loads and environmental conditions while also being easily moldable to achieve the desired part geometry.

Model Part in CAD Considering Walls, Ribs, and Draft Angles

Use Computer-Aided Design (CAD) software to create a detailed model of the part. During this stage, consider factors such as wall thickness, the placement of ribs for added strength, and draft angles to facilitate the ejection of the part from the mold.

Simulate Mold Flow for Filling and Cooling

Before moving to the manufacturing phase, simulate the mold flow to analyze how the material will fill the cavity and cool down. This simulation helps identify potential issues with filling, cooling, and warpage, allowing for necessary adjustments to be made in the design.

Adjust Parting Lines, Undercuts, and Ejection Features

Carefully plan the parting lines and any undercuts or ejection features. These elements are critical for the part’s release from the mold and can significantly impact the complexity and cost of the mold and the manufacturing process.

Prototype and Test Before Mass Production

Once the design is finalized, create a prototype to test the part’s functionality and assess its manufacturability. This phase is invaluable for identifying any last-minute adjustments needed before committing to mass production.

Refine for Cost, Manufacturability, and Aesthetics

After testing, refine the design to optimize costs, ensure ease of manufacturing, and enhance the part’s visual appeal. This may involve tweaking dimensions, surface finishes, or even the choice of material to achieve a balance between performance and aesthetics.

By adhering to this structured design process, you can ensure that the parts you create are not only reliable and functional but also easy to manufacture and visually appealing. This approach minimizes production delays, reduces costs, and enhances the overall quality of the final product.

The most important rule is maintaining uniform wall thickness. Consistent thickness reduces warping, shrinkage, and sink marks, making the part easier to mold and stronger in use.

Material selection depends on product requirements. Consider strength, flexibility, chemical resistance, temperature tolerance, and cost. Common choices include ABS, polypropylene, polycarbonate, and nylon.

Draft angles make it easier to remove the part from the mold without damage. Adding 1–3 degrees of draft helps prevent scratches, stress marks, and sticking inside the mold.

Yes. 3D printing prototypes allows you to test fit, function, and appearance before building an expensive mold. It reduces risk, saves time, and ensures design accuracy.

Successful injection molded parts start with smart design decisions. By carefully planning wall thickness, draft angles, ribs, undercuts, and materials, you can reduce defects, save production costs, and make parts that last. Collaboration with mold designers and prototyping early ensures fewer revisions and smoother manufacturing. Whether you are new to injection molding or looking to optimize your designs, following these principles will make your parts stronger, easier to produce, and more appealing to end users.

At Dongguan Quanhao Plastic Mold Co., Ltd., we bring these principles to life with precision mold design and manufacturing expertise. With years of experience in plastic mold development and injection molding, our team helps clients turn ideas into reliable, high-quality products. If you are ready to create better injection molded parts, partner with Quanhao and achieve efficiency, durability, and excellence in every project.