| Availability: | |

|---|---|

| Quantity: | |

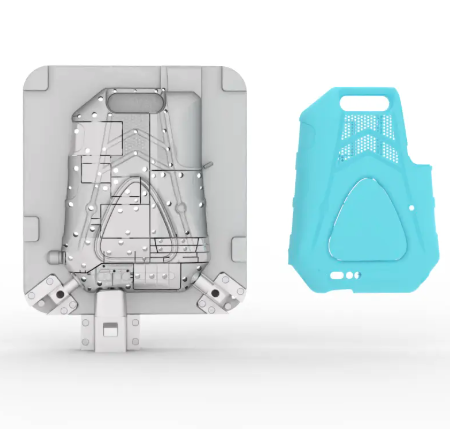

Our custom plastic injection parts cater to diverse industrial needs, from heavy-duty machinery in manufacturing plants to precision robotics in automated facilities. Using a broad range of engineering polymers—including PP, PE, ABS, and high-performance resins like PEEK and PA66—these parts are tailored to deliver high tensile strength (up to 70MPa for PP, 90MPa for ABS), chemical resistance to solvents, oils, and alkalis, and long-term durability in harsh operating environments. The service includes full lifecycle support, from CAD-to-part prototyping (with lead times as short as 5 days for prototypes) to large-scale production (capable of 10 million+ units annually), with dedicated project managers overseeing quality at every stage.

Glass-reinforced PP (30% glass fiber content) provides 120MPa flexural strength for structural components like brackets and support frames, while PEEK variants offer exceptional thermal resistance, withstanding continuous operation at 260°C—making them suitable for high-temperature industrial ovens and aerospace applications.

Anti-static compounds (with surface resistivity ≤10⁹Ω) are used for electronics enclosures and semiconductor manufacturing equipment, preventing electrostatic discharge that could damage sensitive components. For food-contact applications, FDA-compliant PP and PE grades ensure safety and resistance to cleaning agents.

Micro-injection molding capabilities produce miniature parts with 0.5mm wall thicknesses and intricate features like micro-grooves and tiny threaded holes—critical for medical devices and precision sensors. Gas-assisted molding reduces weight by 20% in large components like machine covers and automotive panels, while improving surface finish by eliminating sink marks.

Real-time IoT monitoring systems track critical parameters (e.g., melt temperature, clamp force, cooling time) across all molding machines, providing instant alerts for deviations and ensuring 99.5% first-pass yield—minimizing waste and reducing lead times.

Modular tooling systems allow quick changeovers (≤30 minutes) for low-volume orders (100–5,000 units), reducing setup costs and enabling faster time-to-market. For high-volume runs (100,000+ units), multi-cavity molds (up to 32 cavities) reduce per-unit costs by 40% while maintaining consistent part quality.

Value-added services, such as in-mold labeling, assembly, and packaging, streamline supply chains and eliminate the need for secondary vendors—further reducing total costs for clients.

Energy Sector: Pipe fittings and valve seals resistant to corrosive chemicals in oil refineries and water treatment plants, pump impellers with low friction coefficients for energy efficiency, and cable management components with flame-retardant properties.

Agriculture: Tractor components resistant to fertilizers and pesticides, irrigation system parts with UV stability for outdoor use, and silo liners leveraging weather resistance and impact toughness to withstand grain flow and environmental stress.

Robotics: Gearboxes with dimensional precision for smooth operation, actuators with low moisture absorption, and sensor housings where low friction coefficients (μ ≤0.2) enhance motion efficiency and reduce wear.

Construction: Fasteners and brackets with high load-bearing capacity, insulation parts with thermal resistance, and electrical enclosures combining durability with easy installation for on-site assembly.