Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

Did you know that modern vehicles rely on hundreds of car molded parts to function smoothly and look appealing? From dashboards to bumpers, door panels to hoses, these parts are essential for both performance and design.

Manufacturers use molding techniques to turn plastics, rubbers, and thermoplastic elastomers into precise, durable components. Compared to traditional methods, molding offers speed, cost-effectiveness, and design flexibility, making it a backbone of today’s automotive production.

In this article, we’ll explore what car molded parts are, the materials and processes used, their applications, and why they are vital for the future of vehicles, including electric and hybrid models.

Car molded parts are how we turn plastic or rubber into functional and aesthetic car components. They are used in EVs, PHEVs, and ICE vehicles. They include dashboards, bumpers, door panels, and hoses. Basically, it shapes materials into precise forms using molds.

It’s faster and cheaper than traditional methods. Cars need hundreds of molded parts, so molding keeps production smooth.

Key points:

Shapes plastics, rubbers, TPEs into car molded parts

Works for high-volume production and rapid prototyping

Reduces labor and material costs

Different molding methods are used to create car molded parts:

| Method | Description | Common Use |

|---|---|---|

| Injection Molding | Molten plastic injected into a mold | Dashboards, bumpers, grilles |

| Overmolding | Soft material molded over hard plastic | Motor housings, seals |

| Compression Molding | Heat and pressure shape rubber or plastic | Large panels, engine parts |

| Blow Molding | Air inflates plastic into hollow shapes | Fuel tanks, containers |

They all produce car molded parts that are strong, lightweight, and precise. Overmolding also reduces vibration and noise for better comfort.

Car molded parts need durability, flexibility, and heat resistance. Common materials include:

Polypropylene (PP): Moisture and sunlight resistant, lightweight

ABS: Hard, shiny, ideal for trims and wheel covers

Polycarbonate (PC): Transparent, heat-resistant, for headlights

Acrylic (PMMA): Clear, UV resistant, used in lighting

Nylon (Glass-Filled): Strong, wear-resistant, for gears and latches

TPEs & Silicone: Soft, flexible, absorb vibration and make seals

Material selection depends on:

Durability under heat and UV

Vibration absorption and noise reduction

Recycling potential and environmental impact

Car molded parts are integral to the automotive industry, offering a myriad of benefits that streamline manufacturing processes and enhance vehicle performance:

Injection molded parts contribute to cost-efficiency by reducing material waste and accelerating production cycles, leading to significant long-term savings for manufacturers.

Automated injection molding machines can produce parts at a rapid pace, allowing for quick turnaround times that are essential in the fast-paced automotive sector.

The injection molding process ensures parts with uniform thickness and tight tolerances, guaranteeing a high and consistent level of quality in every component produced.

The technology enables the creation of complex shapes, custom interiors, and exteriors, giving designers the freedom to innovate and differentiate their vehicles in the market.

Plastic components often replace heavier metals, which can improve fuel efficiency and reduce emissions, aligning with the industry’s push towards more sustainable vehicles.

Molded parts are engineered to withstand harsh conditions, including heat, UV exposure, and mechanical stress, ensuring longevity and reliability in automotive applications.

Car molded parts find applications in various areas of vehicle design and function, including:

Dashboards, consoles, door panels, and trims are all common examples of interior components that benefit from the precision and customization offered by injection molding.

Bumpers, grilles, mirrors, and spoilers are exterior components that are often made using molded parts, contributing to the vehicle’s aerodynamics and aesthetic appeal.

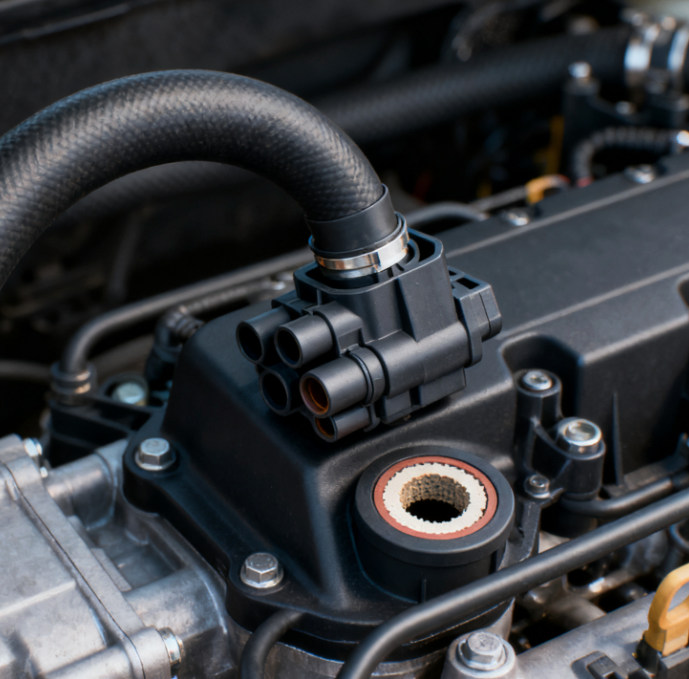

Hoses, connectors, and gaskets are critical functional parts that rely on the durability and reliability of molded materials to perform under demanding conditions.

Specialty Features:

Overmolded parts can be engineered for noise, vibration, and harshness (NVH) control, enhancing the overall driving experience.

Class A surfaces provide premium aesthetics that meet the high standards expected in the automotive industry.

High gloss or textured finishes can be achieved through molding processes, offering both visual appeal and tactile quality.

These molded parts play a crucial role in making cars lighter, quieter, and visually appealing, aligning with consumer expectations and industry advancements.

Recycling matters. Many plastics and TPEs used in car molded parts can be re-melted and molded again. Silicone degrades but still can be recycled in some applications. Manufacturers also use mixed automotive plastic waste to create new molded components.

Why it matters:

Reduces environmental impact

Supports OEM sustainability programs

Lowers material costs

Car molded parts are designed to be durable. Most plastics like ABS, polypropylene, and polycarbonate can last 10–20 years under normal use. Factors like heat, sunlight, and chemical exposure can affect lifespan, but quality parts maintain strength and shape for years.

Not all components can be injection molded. Plastic and rubber parts like dashboards, bumpers, seals, and housings work well. Metals and very large structural parts usually need stamping, casting, or machining.

Overmolding: Soft material is molded over a hard base, like TPE over plastic. It improves grip, reduces vibration, and prevents noise.

Co-molding: Two or more materials are molded together in a single step for integrated designs. Both methods are used in car molded parts to combine strength, flexibility, and comfort.

Many car molded parts are recyclable. Thermoplastics like PP, ABS, PC, and TPE can be melted and molded again. Silicone and thermoset rubbers are harder to recycle, but some processes can repurpose them. Using recyclable materials helps manufacturers reduce waste.

Car molded parts replace heavier metal parts, making vehicles lighter. Lighter cars improve fuel efficiency for ICE vehicles and extend battery range for EVs. Overmolding and design optimization also help remove unnecessary fasteners and reduce material use.

Car molded parts are pivotal in the automotive industry, contributing to the creation of vehicles that are lighter, more durable, and aesthetically pleasing. Advanced molding technologies such as injection molding, overmolding, and blow molding empower manufacturers to produce parts with high precision and quality, all while adhering to contemporary sustainability objectives.

From intricate interior dashboards to robust exterior bumpers and functional seals, molded components not only enhance vehicle performance but also diminish noise and vibration, thus fostering innovative designs that captivate consumers.

When considering the integration of molded parts into your automotive projects, it’s essential to partner with a professional supplier and manufacturer who can deliver on the promise of intelligent, expeditious, and cost-effective production. Dongguan Quanhao Plastic Mold Co., Ltd. stands out as a leader in this domain, offering a comprehensive suite of services that cater to the intricate demands of automotive molding.