| Availability: | |

|---|---|

| Quantity: | |

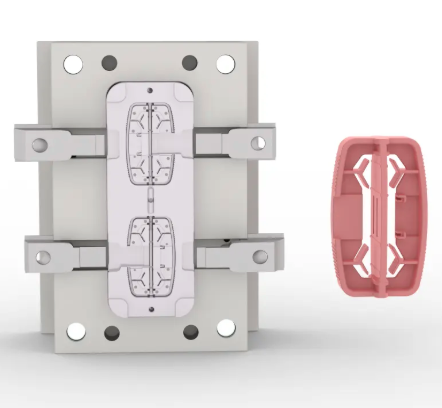

Our custom PVC injection molding solutions are specifically engineered to deliver biocompatible, sterile medical parts that meet the most rigorous regulatory standards for healthcare applications. Using USP Class VI-certified materials—the highest standard for medical plastics—these parts are designed for direct contact with bodily fluids, tissues, and medications. The manufacturing process is conducted in ISO 7 cleanroom environments (equivalent to Class 10,000), where air particle counts are strictly controlled to ≤3,520 particles/m³ (≥0.5μm) and personnel adhere to full sterile gowning protocols. Each part features 100% traceability via laser-engraved batch codes that link to raw material certificates, production parameters, and quality test results.

Materials undergo 12+ biocompatibility tests as specified by ISO 10993, including cytotoxicity (MTT assay), sensitization (guinea pig maximization test), irritation, and thermal stability (70°C/168-hour aging). These tests ensure compliance with FDA 510(k) clearance requirements and EU MDR 2017/745 regulations for medical devices.

Production lines are validated for both gamma irradiation (25–50kGy) and ethylene oxide (EtO) sterilization processes, with residual EtO levels consistently maintained at ≤10ppm—well below the ISO 10993-7 limit of 25ppm.

Molds are precision-machined to achieve ±0.005mm tolerance—critical for components like syringe barrels (where fluid volume accuracy is paramount) and catheter hubs (which require leak-proof connections). High-speed vision systems with 5-megapixel cameras detect defects as small as 0.1mm² during inline inspections, ensuring zero defective parts reach customers.

Mold cooling systems are optimized using computational fluid dynamics (CFD) to prevent warpage in thin-walled parts, such as microfluidic channels with wall thicknesses as low as 0.2mm.

DEHP-free PVC formulations are standard for sensitive applications like blood bags, IV tubing, and neonatal care devices, eliminating the risk of phthalate leaching. For imaging compatibility, radiopaque formulations (infused with barium sulfate or tungsten) enable real-time visualization of implantable devices during X-ray or fluoroscopy procedures.

Custom hardness grades (Shore A 60–90) are available to balance flexibility and rigidity, from soft, kink-resistant tubing to rigid, dimensionally stable valve housings.

Surgical Instruments: Disposable scalpels with ergonomic grips, forceps with precision-molded jaws, and endoscopic components that require lightweight yet rigid structures to maintain positional accuracy during procedures.

Diagnostic Tools: Pipette tips with ultra-precise volume markings, centrifuge tubes resistant to biological fluids, and microfluidic cartridges that leverage PVC’s chemical resistance to acids, bases, and organic solvents.

Patient Care: Oxygen masks with soft, skin-friendly seals, nebulizer parts that prevent medication adsorption, and dialysis connectors designed to ensure low extractables and non-toxicity during long-term use.

Pharmaceutical Packaging: Dropper bottles with leak-proof closures, vial caps with tamper-evident features, and blister packs that combine barrier properties with sterility assurance levels (SAL) of 10⁻⁶—the highest standard for medical packaging.