Views: 0 Author: Site Editor Publish Time: 2025-10-27 Origin: Site

Prices change a lot based on the design, the materials you pick, and how large your project is.

Good design choices can help you spend less, especially if you keep the design simple or choose materials wisely.

It is smart to check both the starting price and extra fees so you do not go over your budget.

Moulding design costs can be from $12,000 to $50,000. The price depends on how hard the design is, what materials you use, and how big the project is. If you pick simple designs and normal materials, you can save a lot of money. This helps you not spend too much. Making prototypes and testing them are very important steps. They help you find problems early. This can stop expensive mistakes from happening later.

When you plan an industrial moulding project, you need to think about many things. These things change how much you pay in the end. Every choice can make your budget go up or down. Let’s look at what matters most.

How hard your moulding design is will change the cost. Simple moulds are faster and cheaper to make. If you want fancy shapes or side-action cores, the price goes up. Adding side-action cores can make tooling cost 15% to 30% more. This means you might pay $1,000 to $1,500 extra. Detailed moulds take longer to make, so you pay more for work and machines.

Here’s a chart that shows how complexity changes cost:

Cost Factor | Simple Moulds | Complex Moulds |

|---|---|---|

Tooling Cost | Lower | Higher |

Production Efficiency | Less efficient | More efficient |

Machine Requirements | Standard machines | Specialized machines |

Maintenance Costs | Lower | Higher |

Tooling Time | Less time | More time |

Overall Cost | More affordable | Higher |

If you keep your design easy, you can control your moulding cost. This helps you avoid budget surprises.

The material you pick for your moulding changes the price and how it works. Plastics cost less than metals because they use less energy and make less waste. Metal prices can change fast, so your cost may go up if the market changes. Composites and premium materials cost more but last longer or look nicer.

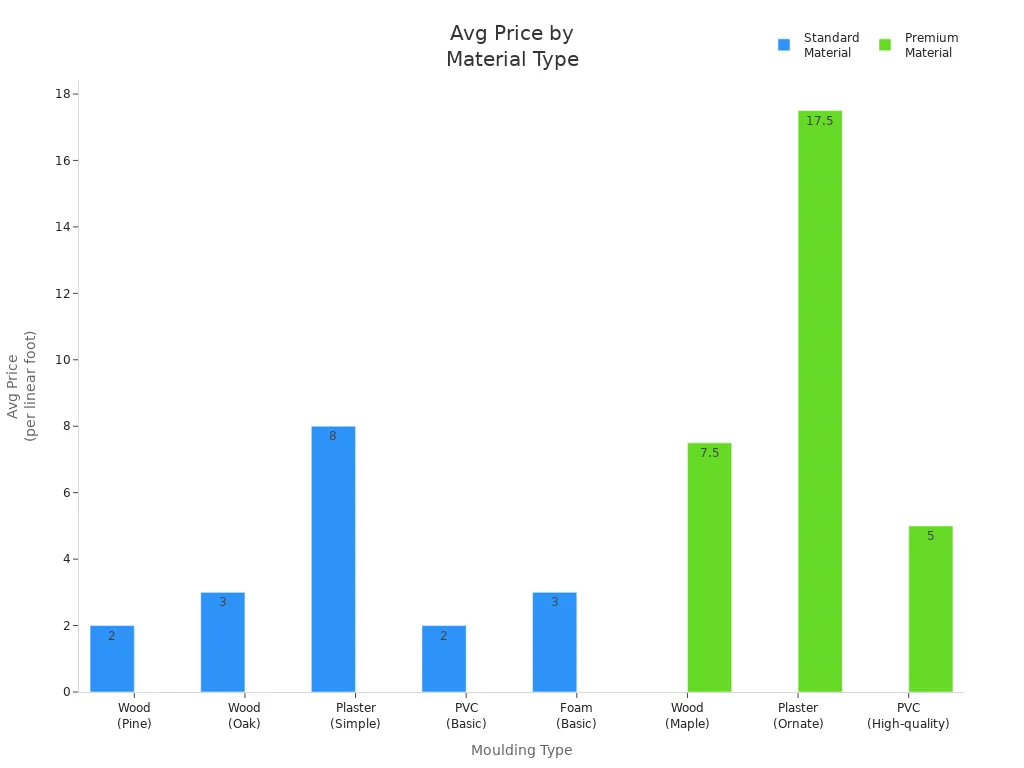

Here’s a chart that shows average costs for different materials:

Moulding Type | Price Range (per linear foot) | Material Type |

|---|---|---|

Wood (Pine) | $1 to $3 | Standard |

Wood (Oak) | $3 to $7 | Standard |

Wood (Maple) | $5 to $10 | Premium |

Plaster (Simple) | $6 to $10 | Standard |

Plaster (Ornate) | $10 to $25 | Premium |

PVC (Basic) | $1 to $3 | Standard |

PVC (High-quality) | $3 to $7 | Premium |

Foam (Basic) | $1 to $5 | Standard |

If you want fancy moulding, premium materials like ornate plaster or maple wood will cost more. Basic PVC or pine helps you spend less.

How big your project is changes the total cost. Bigger parts need larger moulds, so you use more material and spend more time. Small projects cost less for moulds and making parts. Big projects cost more, especially if you want special features.

Here’s a chart that shows how project size changes cost:

Production Volume | Number of Parts | Cost of Mold | Cost per Part | Total Cost of Injection Molding |

|---|---|---|---|---|

Low Volume | 100 | $100 | $4.5 | $450 |

Medium Volume | 5,000 | $2,500 | $3 | $15,000 |

Large Volume | 100,000 | $25,000 | $1.75 | $175,000 |

If you make lots of parts, each part costs less. But you pay more at the start for moulding design.

Do you want special shapes, cool finishes, or tight fits? Customization makes your moulding unique, but it costs more. Engraving, undercuts, and fancy finishes need special tools and more time. If you pick a fancy finish or shape, plan for higher costs and extra steps.

Tip: Custom decorative moulding looks nice, but check how much each feature costs before you choose.

Engineering services are important for your moulding design cost. You pay experts to help with design, picking materials, and how to make things. If your mould is big or has lots of details, you need more engineering time. This makes your budget go up. These services also cover using equipment, paying workers, and buying materials. Make sure you add them to your total cost.

Engineering services help you avoid mistakes.

They make sure your moulding works for your project.

You pay more for hard designs and bigger moulds.

Prototyping and testing help you find problems early. This makes sure your moulding works before you make a lot. Simple prototypes cost less, but hard designs or premium materials make this step pricey. If you skip prototyping, you might have expensive mistakes and delays later.

Here’s a chart that shows average costs for different prototyping methods:

Prototyping Method | Cost Range |

|---|---|

Foam core & foam mock-ups | $100+ |

3D printing (FDM, SLA, SLS) | $100-$1,000 |

Laser cutting | $25-$100 |

Urethane casting | $250-$1,500 per mold |

Appearance models | $2,000-$150,000 |

Engineering prototypes | $2,000-$250,000 |

Low-volume production | $20-$200 per unit |

Prototyping lets you change your design before you decide.

Testing makes sure your moulding does what you need.

You save money by fixing problems early.

Prototyping is a key step that can help your project work well and save money. By finding and fixing mistakes during testing, you avoid delays and extra costs. This saves you time and money.

When you look at all these things, you see how each choice changes your moulding design cost. If you want to keep your budget safe, think about complexity, materials, project size, customization, engineering, and testing before you start. This way, you get the moulding you want without spending too much.

When you plan a moulding project, you want to know what you might pay. The moulding design cost changes a lot based on your project size, the type of trim, and how fancy you want your crown molding. Let’s break down the average costs for small, medium, and large projects. You’ll also see what to expect for crown molding and the cost to install crown molding.

Small projects often mean you want to add a bit of trim or crown moulding to a single room or a small area. These jobs use less material and need less time. The moulding design cost for small jobs can start low, but it still depends on your choices.

Project Scale | Average Cost |

|---|---|

Small-scale | Varies widely |

Medium-scale | Approx. $12,000 |

Large-scale | Higher costs |

For small-scale moulding, you might pay between $6 and $25 per linear foot. Kits for simple crown molding or decorative trim can cost $99 to $675. If you want design services, expect to pay $159.99 to $499.99. The cost per linear foot goes up if you pick custom crown molding or premium materials.

You pay less for basic MDF or PVC crown molding.

Decorative moulding and custom crown molding cost more.

The cost to install crown molding in a small room can range from $1 to $4 per linear foot for materials, plus labor.

Tip: For small projects, keep your design simple and use standard trim to stay within your budget.

Medium projects cover several rooms or a whole floor. The moulding design cost here jumps because you need more trim and more work. The average cost for a medium project is about $12,000. This price includes materials, design, and crown molding installation.

Key things that affect your cost:

Mold size and complexity: Bigger or more detailed moulds need more work.

Tooling material: Aluminum costs less, but steel lasts longer.

Mold life expectancy: Longer-lasting moulds cost more at first but save money over time.

Number of cavities: More cavities can lower the cost per part but raise the starting price.

Part design: Simple shapes cost less to make.

You might pay $6 to $25 per linear foot for crown molding or decorative trim. Kits and design services still help you save money, but custom crown molding will raise your total. The cost to install crown molding for a medium project can reach $2,000 to $8,000, depending on the number of rooms and the type of moulding.

Note: Always check the cost per linear foot for each type of trim. This helps you compare prices and pick what fits your budget.

Large or complex projects mean you want moulding for a whole building, a big industrial space, or you want very detailed crown molding. The moulding design cost here gets much higher. You pay more for advanced engineering, special materials, and custom crown molding installation.

Factor | Description |

|---|---|

Tooling Complexity | Complex designs need advanced engineering and precision work, raising costs. |

Production Volume | Making more parts lowers the cost per part, but you pay more at the start. |

Material Selection | High-quality materials cost more but last longer. |

Initial Investment | You pay a lot up front, but it spreads out over many parts. |

Design Efficiency | Good design saves money by using less material and time. |

For large projects, the cost per linear foot for custom crown molding can reach $10 to $30 for materials. Labor for crown molding installation adds $15 to $20 per linear foot. The total cost to install crown molding in a large space can go over $50,000. If you want decorative or custom crown molding, expect the moulding design cost to rise fast.

Complex moulds need more engineering and testing.

Multi-cavity moulds help you make more parts but cost more to build.

Higher production volume lowers the cost per part.

Callout: If you plan a big project, talk to a moulding expert early. They can help you pick the right trim and avoid surprise costs.

Crown molding gives your space a finished look. The cost to install crown molding depends on the material, the design, and how much trim you need. Here’s a quick look at average costs:

Type of Molding | Cost per Linear Foot |

|---|---|

Crown Molding (MDF) | $1 to $4 |

PVC Crown Molding | $1 to $4 |

Polystyrene Foam | $1 to $4 |

Metal Crown Molding | $10 to $30 |

Custom Crown Molding | $10 to $30 (materials) + $15 to $20 (labor) |

You pay less for basic MDF or PVC crown molding. Custom crown molding and metal trim cost more. The cost to install crown molding includes both the price of the moulding and the labor. For most homes, the cost per linear foot for crown molding installation is $1 to $4 for materials and $4 to $15 for labor. Custom crown molding installation can reach $30 to $50 per linear foot.

Decorative crown moulding adds style but raises the cost.

The cost to install crown molding in a whole house can range from $2,000 to $15,000.

Always ask for a quote before you start your crown molding installation.

Tip: Measure your rooms and count the corners. This helps you estimate the total cost to install crown molding and avoid buying too much trim.

You can estimate your moulding design cost by following a few steps:

Evaluate the complexity of your project. Simple trim costs less than decorative or custom crown molding.

Consider the material options. MDF and PVC cost less, while metal and custom crown molding cost more.

Assess the production volume. More trim means a higher total cost, but the cost per linear foot may drop.

Use online tools like injection molding cost calculators or 3D modeling software. These help you figure out material needs and average costs.

Compare quotes from different moulding suppliers and installers. Look at both the cost per linear foot and the total cost to install crown molding.

Method Type | Description |

|---|---|

Intuitive Method | Use your experience to guess the cost. Good for quick estimates. |

Analogy Method | Compare your project to past jobs. Helps if you have records. |

Parametric Method | Use numbers like length, width, and material to estimate the cost. |

Analytical Method | Break the job into steps and add up each cost. Most detailed, but takes more time. |

You can also use apps and calculators to help with your estimate. Many 3D modeling programs let you measure your trim and see how much material you need. Some apps give you quick average costs for different types of crown molding and decorative trim.

Note: Always add a little extra to your budget for surprises. This keeps your moulding project on track and helps you avoid stress.

Now you know how moulding design cost changes with project size, material, and the type of crown molding you choose. Use these tips to plan your trim, control your budget, and get the look you want.

You have learned that moulding design cost can go up or down. Always get a quote that lists material, labor, and tooling. When you plan, look at these things:

Mold size and complexity

Material selection

Production volume

Runner system

Operator load

Planning ahead helps you avoid errors and keeps your cost steady.

You can expect most moulding designs to take 2 to 8 weeks. Complex projects may need more time. Ask your designer for a timeline.

Yes! Standard moulding costs less than custom designs. You also get faster delivery. If you want to save, pick simple shapes and common materials.

Get quotes from several suppliers. Share your project details and ask for a breakdown of costs. This helps you compare and choose the best option.