Views: 0 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

Thermoforming is a manufacturing process that involves heating a plastic sheet until it becomes pliable, then shaping it over a mold to create a specific form. Once cooled, the shaped plastic retains the desired shape and is trimmed to produce the final product. This technique is widely used due to its efficiency, cost-effectiveness, and ability to produce detailed and lightweight components.

In the packaging and consumer goods industries, thermoforming plays a vital role. It enables the production of a diverse range of products, from protective packaging like blister packs and clamshells to durable consumer items such as appliance panels and product housings. The process supports customization, fast turnaround times, and scalability, making it essential for meeting market demands while controlling costs.

Thermoforming is widely used to manufacture various types of packaging that protect and display products effectively. Common packaging forms include:

Blister Packs: Clear plastic shells often used for small consumer goods, pharmaceuticals, and electronics, allowing product visibility while ensuring protection.

Clamshells: Hinged two-part packages that securely encase products, popular for retail items like toys, tools, and hardware.

Trays: Custom-shaped trays that hold and organize products, commonly used for food packaging, medical instruments, and electronics.

Containers: Durable thermoformed containers designed for food storage, cosmetics, and other consumer goods, providing airtight and protective solutions.

Thermoforming offers multiple advantages that make it a preferred packaging method:

Lightweight: The process produces thin yet strong packaging, reducing shipping costs and environmental impact.

Cost-Effectiveness: Thermoforming requires relatively low tooling costs compared to other molding methods, especially for medium to large production runs, enabling competitive pricing.

Product Protection: Thermoformed packaging provides excellent physical protection, cushioning products from damage during transport and handling while maintaining visibility and accessibility.

Thermoforming allows extensive customization to meet both branding and functional needs:

Branding: Packaging can be designed with custom shapes, sizes, and features that enhance shelf appeal and reinforce brand identity. Printing and embossing options further increase visual impact.

Functional Features: Packaging can include compartments, hinges, locking mechanisms, and tamper-evident seals tailored to the product’s requirements, improving usability and security.

Material Choices: A wide variety of plastics can be thermoformed, including recyclable and biodegradable options, allowing brands to address sustainability goals.

Thermoforming is widely applied across various consumer goods to produce functional and visually appealing components, including:

Appliance Panels: Thermoformed plastic panels are commonly used in household appliances such as refrigerators, washing machines, and microwaves. These panels provide durable, lightweight, and aesthetically pleasing surfaces that protect internal components while enhancing product design.

Toys: Many toys feature thermoformed parts due to the process’s ability to create intricate shapes and colorful designs. Thermoforming allows manufacturers to produce safe, durable, and affordable toy components with smooth edges and consistent quality.

Product Casings: Consumer electronics, handheld devices, and small gadgets often use thermoformed casings that combine lightweight protection with customizable shapes and finishes. These casings help protect sensitive electronics and improve ergonomic handling.

Thermoforming offers several benefits that make it ideal for consumer product manufacturing:

Design Flexibility: The process supports a wide range of shapes, sizes, and textures, enabling manufacturers to create unique and complex designs that stand out in the market. This flexibility helps brands tailor products to specific consumer preferences and trends.

Quick Production Turnaround: Thermoforming is known for its fast tooling and short production cycles. This speed allows manufacturers to respond quickly to market demands, launch new products faster, and adapt designs efficiently without high upfront costs.

Cost Efficiency: Compared to other molding methods, thermoforming has lower tooling expenses, especially for medium-volume production, making it a cost-effective choice for many consumer goods.

Durability and Lightweight: Thermoformed parts offer a good balance of strength and lightness, improving product usability and reducing shipping costs without compromising quality.

Thermoforming utilizes a variety of plastic materials, each suited to different product requirements and applications:

PVC (Polyvinyl Chloride): Known for its excellent clarity and toughness, PVC is widely used in packaging and display products. It offers good chemical resistance and is easy to thermoform into detailed shapes.

PET (Polyethylene Terephthalate): PET is favored for its superior strength, transparency, and barrier properties. It is commonly used in food packaging and blister packs where product visibility and protection are critical.

Polystyrene (PS): Polystyrene is lightweight and cost-effective, making it popular for disposable trays, containers, and product housings. It provides good stiffness but is less impact-resistant compared to other plastics.

Polypropylene (PP): PP offers excellent chemical resistance, flexibility, and durability. It is often used for reusable containers, packaging, and consumer goods that require toughness and heat resistance.

Choosing the right plastic for thermoforming depends on several key factors:

Strength and Durability: Depending on the application, materials need to provide adequate mechanical strength to withstand handling, shipping, and usage conditions without cracking or deforming. For example, PP and PET offer higher durability for reusable packaging and consumer goods.

Clarity and Aesthetics: For products where transparency is important, such as food packaging or display cases, materials like PET and PVC are preferred due to their excellent optical properties.

Recyclability and Environmental Impact: Sustainability is increasingly important in material selection. Many thermoforming plastics, like PET and PP, are recyclable, supporting circular economy initiatives. Manufacturers must balance performance needs with environmental considerations to meet regulatory and consumer demands.

Chemical and Temperature Resistance: Some applications require resistance to chemicals, moisture, or temperature variations. Materials like PP and PVC can offer these properties, ensuring product integrity in different environments.

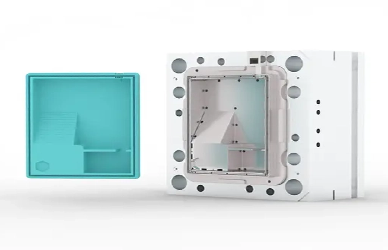

Thermoforming is known for its relatively quick and cost-effective tooling process compared to other plastic forming methods. The molds used in thermoforming are typically less expensive and faster to produce, which reduces initial setup times and costs. This makes thermoforming especially suitable for short to medium production runs, prototyping, and rapid product launches. Manufacturers benefit from lower investment risks and the ability to respond quickly to market demands.

Thermoforming allows for the creation of detailed and intricate shapes with smooth surface finishes, enhancing the aesthetic appeal of packaging and consumer goods. The process can accommodate a wide variety of designs, including deep draws, textured surfaces, and custom contours, which are important for product differentiation and branding. Additionally, thermoformed parts often require minimal post-processing, which saves time and improves production efficiency.

Sustainability is a growing concern in packaging and consumer products industries, and thermoforming supports this trend by using recyclable materials such as PET, PP, and PS. Many thermoformed products can be designed for easy recycling, helping reduce environmental impact. Moreover, advances in bio-based and recycled plastics are expanding the range of eco-friendly materials compatible with thermoforming, enabling manufacturers to meet regulatory requirements and consumer preferences for greener products.

Thermoforming plays a vital role in both the packaging and consumer goods industries by offering a versatile and efficient manufacturing method. It enables the production of lightweight, durable, and visually appealing packaging and product components that meet the demands of modern consumers and businesses. With fast and cost-effective tooling, the ability to create complex shapes, and compatibility with recyclable materials, thermoforming supports both functional and sustainable solutions.

For companies seeking innovative product designs, faster production cycles, and environmentally friendly options, thermoforming is an excellent choice. To learn more about how thermoforming can benefit your packaging or consumer goods projects, consider contacting Dongguan Quanhao Plastic Mold Co., Ltd. With their expertise and advanced capabilities, they provide professional thermoforming services tailored to your specific needs. Visit www.qhpmould.com to discover more and get in touch with their expert team today.