Views: 0 Author: Site Editor Publish Time: 2025-10-18 Origin: Site

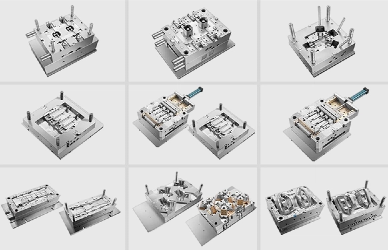

Plastic molds are essential tools in modern manufacturing, enabling the mass production of precise and complex parts by shaping molten plastic into desired forms. This technology offers high efficiency, repeatability, and cost-effectiveness, making it a cornerstone in various industries.

In the medical device industry, plastic molding plays a crucial role due to the need for high-precision, hygienic, and reliable components. From syringes to diagnostic housings, plastic molds allow manufacturers to produce medical parts that meet strict quality and safety standards, ensuring patient safety and advancing healthcare innovation.

Plastic molds are fundamental for manufacturing medical components that require intricate designs and fine details. The molding process allows the creation of complex geometries with high accuracy, essential for devices like syringes, implants, and diagnostic tools. This precision ensures that medical parts function correctly and fit perfectly within larger assemblies.

Consistency in production is key for medical devices, where even small variations can affect safety and effectiveness. Plastic molds are engineered to maintain tight dimensional tolerances, ensuring each part meets exact specifications. This repeatability reduces defects and enhances the reliability of the final product.

Medical device manufacturing must comply with strict regulatory standards (such as FDA and ISO). Plastic molding processes help manufacturers achieve these requirements by producing parts with uniform quality and minimizing contamination risks. Proper mold design and manufacturing controls are essential for passing regulatory inspections and ensuring patient safety.

Plastic molds are fundamental for manufacturing medical components that require intricate designs and fine details. The molding process allows the creation of complex geometries with high accuracy, essential for devices like syringes, implants, and diagnostic tools. This precision ensures that medical parts function correctly and fit perfectly within larger assemblies.

Consistency in production is key for medical devices, where even small variations can affect safety and effectiveness. Plastic molds are engineered to maintain tight dimensional tolerances, ensuring each part meets exact specifications. This repeatability reduces defects and enhances the reliability of the final product.

Medical device manufacturing must comply with strict regulatory standards (such as FDA and ISO). Plastic molding processes help manufacturers achieve these requirements by producing parts with uniform quality and minimizing contamination risks. Proper mold design and manufacturing controls are essential for passing regulatory inspections and ensuring patient safety.

Injection molding is the most widely used plastic molding technique in the medical device industry. It involves injecting molten plastic into a mold cavity under high pressure. This method is ideal for producing complex and precise parts with tight tolerances. Medical components such as syringes, inhalers, and surgical instrument housings are commonly made using injection molding due to its high accuracy and repeatability. Its ability to produce large volumes efficiently makes it suitable for both small and mass production runs.

Blow molding is primarily used to manufacture hollow medical parts like bottles, containers, and fluid reservoirs. In this process, heated plastic is inflated inside a mold to form a hollow shape. Blow molding offers advantages such as lightweight parts, cost-effectiveness, and fast production times. It is especially useful for producing medical packaging and disposable fluid containers that require high strength and flexibility.

Compression Molding: Often used for thermoset plastics, this technique is suitable for creating durable parts like medical device casings and connectors. It allows for high-strength components with excellent dimensional stability.

Rotational Molding: Used for producing large, hollow parts with uniform wall thickness, such as medical equipment housings or trays. This method provides cost-effective manufacturing for bulky components.

Thermoforming: Involves heating plastic sheets and forming them over molds. It is ideal for creating trays, covers, or packaging used in medical settings, offering quick turnaround and lower tooling costs.

Each molding method offers unique benefits suited to specific medical device requirements:

Injection molding excels in precision and complexity, essential for intricate medical parts.

Blow molding is best for lightweight, hollow containers and packaging.

Compression molding provides strength and durability for robust components.

Rotational molding is cost-effective for large, hollow parts.

Thermoforming offers flexibility and speed for packaging and disposable medical items.

Choosing the right molding technique depends on the medical device’s design, material requirements, production volume, and cost considerations. This selection ensures optimal performance, safety, and regulatory compliance in medical manufacturing.

Medical plastic molding relies on specialized materials that meet strict safety and performance standards. The most commonly used medical-grade plastics include:

Polypropylene (PP): Known for its chemical resistance, low cost, and versatility. PP is widely used in disposable medical products like syringes, specimen containers, and medical packaging.

Polyethylene (PE): Offers excellent chemical resistance and flexibility. PE is often used for tubing, bags, and containers in medical applications.

Acrylonitrile Butadiene Styrene (ABS): A strong, impact-resistant plastic used in durable medical device housings and components. ABS provides good mechanical properties and surface finish.

Polycarbonate (PC): Known for its toughness and transparency, PC is used in devices requiring clarity and durability, such as surgical instruments and diagnostic equipment.

Polymethyl Methacrylate (PMMA): Often chosen for optical clarity and biocompatibility, used in lenses and medical displays.

Biocompatibility is a critical property for medical plastics, ensuring that materials do not cause adverse reactions when in contact with the human body. Medical-grade plastics are rigorously tested and certified to be non-toxic, non-allergenic, and safe for direct or indirect contact with tissues, fluids, or implants. This property is essential for components such as implants, surgical tools, and diagnostic devices.

Medical plastics must withstand various sterilization methods used to maintain hygiene and prevent contamination, including:

Autoclaving (steam sterilization): Requires materials that resist high heat and pressure without deforming.

Ethylene oxide (EtO) sterilization: Requires chemical resistance to avoid degradation.

Gamma irradiation: Demands resistance to radiation-induced material changes.

Materials selected for medical molding must maintain their mechanical properties, dimensional stability, and safety after repeated sterilization cycles.

Chemical Resistance: Essential to prevent degradation from exposure to bodily fluids, medications, and cleaning agents.

Durability and Strength: Required for components subjected to mechanical stress or frequent use.

Transparency: Important for diagnostic devices or parts needing visual inspection.

Plastic molded parts are fundamental in the manufacture of a wide range of medical devices due to their precision, cost-effectiveness, and versatility. Key examples include:

Syringes: Precision-molded plastic components such as barrels, plungers, and caps that require tight tolerances for accurate dosing and safe administration.

Surgical Instruments: Lightweight, disposable or reusable tools like forceps, clamps, and scissors often made using high-quality plastic molds for strength and sterilizability.

Diagnostic Components: Parts like test cartridges, sample holders, and housings for diagnostic devices, where clarity and accuracy are vital.

Housings and Casings: Durable plastic shells for electronic medical devices, monitoring equipment, and handheld tools that protect sensitive internal components while being lightweight and ergonomic.

The medical device industry increasingly requires highly customized molded parts to meet specific patient needs and device functionalities. Custom molds allow for:

Tailored geometries suited for specialized medical procedures.

Integration of multi-material components for enhanced performance.

Adaptability to rapidly evolving medical technologies.

Disposable plastic molded parts play a crucial role in maintaining hygiene and preventing cross-contamination in healthcare settings. These single-use components include:

Needles and syringes designed for safe, sterile use.

Catheters, tubes, and connectors that minimize infection risks.

Packaging and protective cases for sterile medical products.

Plastic molds play a vital role in advancing medical device manufacturing by enabling the production of precise, high-quality, and cost-effective components essential for modern healthcare. As medical technology evolves, plastic molding continues to innovate with techniques like micro-molding and multi-material processes, meeting the growing demands for complex, safe, and reliable medical parts.

For cutting-edge plastic molding solutions tailored to the medical industry, consider contacting Dongguan Quanhao Plastic Mold Co., Ltd. Their expertise and advanced technologies ensure superior quality and efficient production to support your medical device projects. Visit www.qhpmould.com to learn more or get in touch with their professional team today.