Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

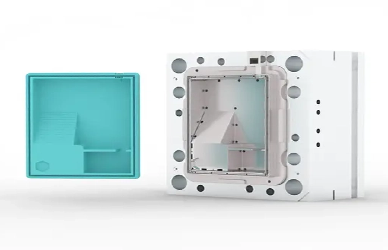

3D printing, also known as additive manufacturing, is a cutting-edge technology that builds objects layer by layer from digital designs. It allows for the rapid creation of complex and precise parts without the need for traditional tooling or molds. This flexibility makes 3D printing especially valuable for small batch production and rapid prototyping, where quick turnaround and customization are critical. By enabling faster design iterations and cost-effective low-volume manufacturing, 3D printing plays a crucial role in accelerating product development and meeting specialized production needs.

3D printing offers several significant benefits that make it an ideal choice for small batch production.

Traditional manufacturing processes like injection molding or CNC machining often involve high upfront costs due to expensive tooling, mold creation, and setup. These costs are justified when producing large volumes but can be prohibitively expensive for small batches. In contrast, 3D printing eliminates the need for specialized molds and tooling altogether. By building parts layer by layer directly from digital models, 3D printing drastically reduces initial investment, making small production runs economically viable. This means startups, small businesses, and product developers can manufacture prototypes or limited series without breaking the budget.

One of the standout advantages of 3D printing is its unmatched design freedom. Unlike traditional subtractive or molding methods, 3D printing can easily produce complex geometries, intricate internal structures, and fine details that are difficult or even impossible to achieve with conventional manufacturing. This capability allows companies to customize parts to exact specifications without additional cost or tooling changes. Whether it’s lightweight lattice structures, optimized fluid channels, or bespoke components tailored for unique applications, 3D printing offers unparalleled adaptability for producing highly specialized, personalized products.

3D printing streamlines the production process by bypassing many time-consuming steps required in traditional manufacturing, such as mold fabrication and machine setup. Once a digital design is finalized, parts can be printed almost immediately, dramatically cutting lead times. This speed is invaluable for rapid prototyping, enabling quick testing, validation, and design iterations. Faster production cycles allow businesses to bring products to market more swiftly, respond rapidly to customer feedback, and stay ahead in competitive industries. The ability to quickly adapt and produce small batches also supports just-in-time manufacturing, reducing inventory costs and minimizing waste.

3D printing has become an essential technology for speeding up the product development process by enabling rapid prototyping.

3D printing enables the swift production of accurate, functional prototypes directly from detailed digital CAD models. This rapid fabrication process drastically shortens the time it takes to transform concepts into physical models. Designers and engineers can quickly evaluate a prototype’s form, fit, and function, identifying potential design flaws, usability issues, or performance gaps early in development. Early detection of problems reduces costly revisions later and helps ensure that the final product meets quality and performance expectations before mass production begins.

One of the biggest advantages of 3D printing is the ease of making design modifications. Unlike traditional prototyping methods that require new molds or tooling, 3D printing can produce updated prototypes quickly and cost-effectively. This facilitates multiple iterations, enabling teams to refine product features and optimize performance based on real-world testing and user feedback.

By drastically shortening the time between design revisions and prototype testing, 3D printing significantly reduces the overall product development timeline. This accelerated process allows companies to make faster decisions, minimize costly errors, and bring innovative products to market more quickly, giving them a competitive edge.

3D printing encompasses various technologies, each suited for specific materials, applications, and production needs. The most popular methods include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

FDM is one of the most widely used 3D printing techniques, especially popular for prototyping and small batch production. It works by extruding melted thermoplastic filament layer by layer to build the part. FDM is suitable for materials like ABS, PLA, and PETG. It offers good strength and affordability, making it ideal for functional prototypes, simple mechanical parts, and educational models.

SLA uses a laser to cure liquid resin into solid layers, producing highly detailed and smooth surface finishes. This technology excels in creating parts with fine features and tight tolerances. SLA is often chosen for applications requiring high precision and aesthetic quality, such as jewelry, dental models, and intricate prototypes. However, SLA resins may be more brittle and less suited for functional testing.

SLS employs a laser to fuse powdered materials—usually nylon or other polymers—into solid parts. It produces strong, durable components without the need for support structures, making it excellent for complex geometries and functional end-use parts. SLS is commonly used in automotive, aerospace, and industrial applications where mechanical strength and heat resistance are important.

3D printing encompasses various technologies, each suited for specific materials, applications, and production needs. The most popular methods include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

FDM is one of the most widely used 3D printing techniques, especially popular for prototyping and small batch production. It works by extruding melted thermoplastic filament layer by layer to build the part. FDM is suitable for materials like ABS, PLA, and PETG. It offers good strength and affordability, making it ideal for functional prototypes, simple mechanical parts, and educational models.

SLA uses a laser to cure liquid resin into solid layers, producing highly detailed and smooth surface finishes. This technology excels in creating parts with fine features and tight tolerances. SLA is often chosen for applications requiring high precision and aesthetic quality, such as jewelry, dental models, and intricate prototypes. However, SLA resins may be more brittle and less suited for functional testing.

SLS employs a laser to fuse powdered materials—usually nylon or other polymers—into solid parts. It produces strong, durable components without the need for support structures, making it excellent for complex geometries and functional end-use parts. SLS is commonly used in automotive, aerospace, and industrial applications where mechanical strength and heat resistance are important.

3D printing provides significant advantages in small batch manufacturing and rapid prototyping, such as cost savings, design flexibility, and faster turnaround times. Its ability to create complex, customized parts without expensive tooling makes it an ideal solution for modern product development. With ongoing technological advances, 3D printing will continue to improve in precision, efficiency, and accessibility, reshaping how businesses innovate and manufacture.

For companies looking to leverage the full potential of 3D printing in their projects, Dongguan Quanhao Plastic Mold Co., Ltd. offers professional expertise and high-quality services. To learn more about their 3D printing solutions or to discuss your specific needs, we highly recommend contacting Dongguan Quanhao Plastic Mold — your trusted partner in advanced molding and prototyping technologies.